The Role of Advanced Composites in Car Parts

all pannel.com, cricket bet99, lotus365 vip login:The automotive industry is constantly evolving, with manufacturers always on the lookout for innovative materials that can help improve the performance, efficiency, and safety of vehicles. In recent years, advanced composites have emerged as a game-changer in the production of car parts. These materials offer a wide range of benefits, from reducing weight to improving strength and durability. In this blog post, we will explore the role of advanced composites in car parts and how they are revolutionizing the automotive industry.

Lightweight and Durable

One of the key advantages of advanced composites is their lightweight nature. These materials are typically made up of a combination of fibers, such as carbon fiber or fiberglass, embedded in a matrix material, such as resin. This combination results in a material that is significantly lighter than traditional metal counterparts, such as steel or aluminum. Lighter car parts mean reduced vehicle weight, which in turn can lead to improved fuel efficiency and better overall performance.

But don’t let their lightweight fool you – advanced composites are also incredibly durable and strong. In fact, they are often stronger than steel pound for pound, making them ideal for use in critical car parts that require high tensile strength, such as chassis components, body panels, and suspension parts. Their high strength-to-weight ratio also means that advanced composites can help improve a vehicle’s crashworthiness, providing better protection for occupants in the event of a collision.

Improved Aerodynamics

Another benefit of using advanced composites in car parts is their ability to enhance aerodynamics. These materials can be shaped and molded into complex, streamlined forms that help reduce drag and improve airflow around the vehicle. By incorporating advanced composites in components such as spoilers, splitters, and diffusers, manufacturers can optimize a car’s aerodynamic performance, leading to better handling, stability, and fuel efficiency.

Innovative Design Possibilities

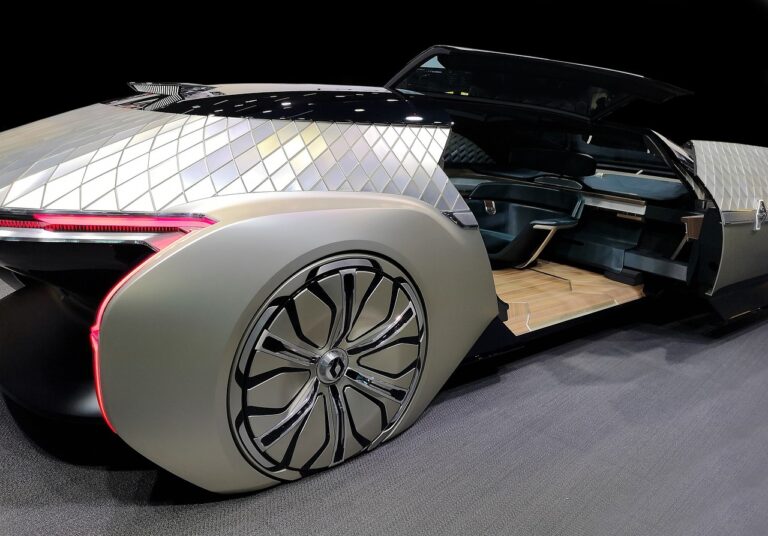

Advanced composites also offer designers a level of flexibility and freedom that is not possible with traditional materials. These materials can be molded into virtually any shape or form, allowing for more innovative and creative designs. This flexibility enables manufacturers to create lightweight, complex, and aesthetically pleasing car parts that are both functional and visually appealing.

Additionally, advanced composites can be tailored to meet specific performance requirements, such as stiffness, impact resistance, or heat tolerance. This level of customization allows engineers to optimize the material properties of each component for its intended application, resulting in parts that are highly efficient and effective in their function.

Cost Considerations

While the benefits of using advanced composites in car parts are undeniable, it’s important to consider the cost implications of these materials. Advanced composites are generally more expensive to produce than traditional metals, which can drive up the overall manufacturing costs of a vehicle. However, the long-term benefits, such as improved fuel efficiency, durability, and performance, often outweigh the initial investment in advanced composites.

Furthermore, advancements in material manufacturing technologies are helping to drive down the cost of producing advanced composites, making them more accessible to car manufacturers of all sizes. As production techniques continue to evolve and improve, we can expect to see a wider adoption of these materials in the automotive industry.

In conclusion, advanced composites are playing a crucial role in shaping the future of car parts. Their lightweight, durable, and aerodynamic properties are helping manufacturers create vehicles that are more efficient, safer, and aesthetically pleasing. While cost considerations remain a factor, the numerous benefits of using advanced composites make them a compelling choice for car manufacturers looking to stay ahead of the curve. As technology continues to advance, we can expect to see even more innovative uses of these materials in future vehicle designs.

FAQs

Q: Are advanced composites safe to use in car parts?

A: Yes, advanced composites are rigorously tested for safety and performance to ensure they meet or exceed industry standards for strength, durability, and crashworthiness.

Q: Do advanced composites require special maintenance or care?

A: While advanced composites are generally more durable than traditional materials, it’s important to follow manufacturer guidelines for maintenance and care to ensure their longevity and performance.

Q: Can advanced composites be repaired if damaged?

A: Yes, advanced composites can be repaired using specialized techniques and materials. It’s recommended to consult with a professional repair service for any damage to composite car parts.